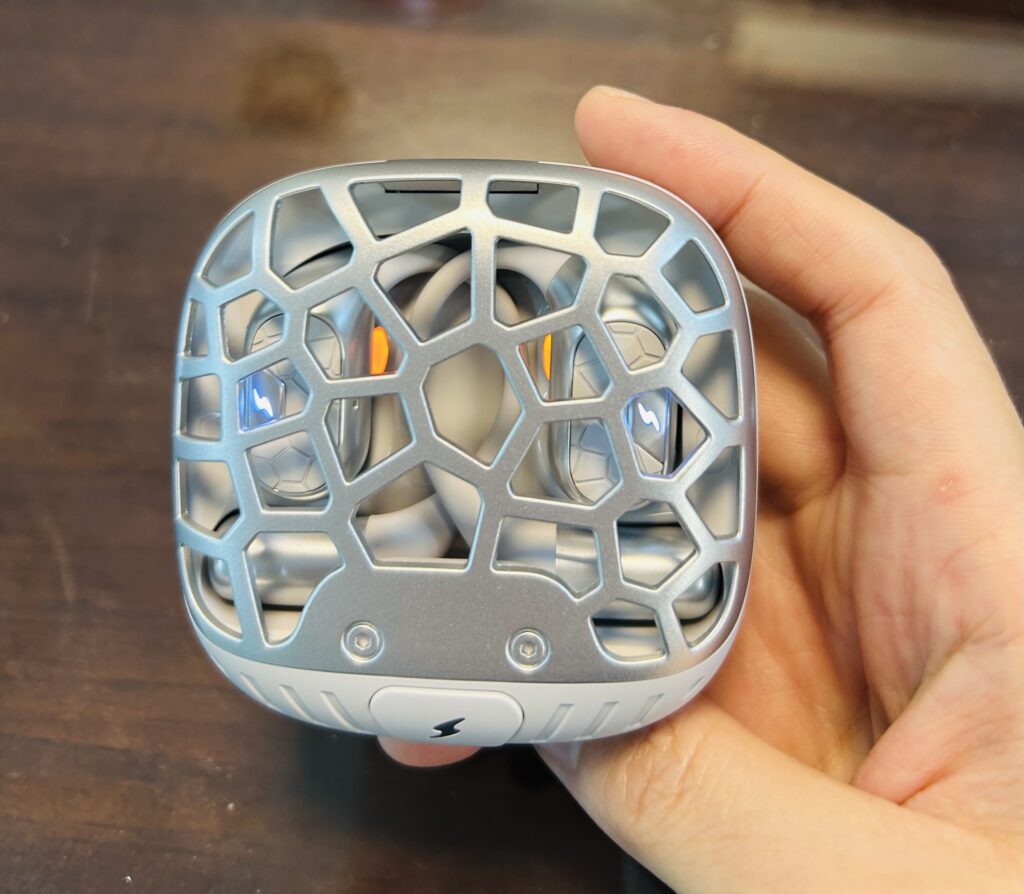

The CNC machining cost for aluminum alloy is very high, and excessive detail processing techniques make the material cost of the casing alone extremely expensive. However, this also allows high-end brands to elevate their brand tier in the market. Design innovation for ordinary plastic-casing earphones has become difficult to break through. Many brands adopt spray coating techniques and licensed ID methods to shape their product image. Yet, we have discovered a highly representative new design approach for aluminum alloy earphones—the Medusa Earphones. Whether in terms of form, ambient lighting colors, or texture treatments, all evoke strong associative imagery. Its sleek, domineering serpentine design subconsciously conveys a powerful aesthetic.

Video here:

If someone asks you about metal TWS earphones, does the first impression in your mind still resemble the relatively traditional square-shaped or basic circular metal charging case versions shown in the image below?

Earphones are far too ordinary and a bit outdated, aren’t they?

The aluminum alloy casing of the Medusa model features a same-mother-sibling design, with spray oil effects that are strongly brilliant.

These two Medusa earphones share largely identical designs from the charging case exterior to the earpiece appearance. Customization can involve redeveloping a new charging case exterior or creating custom molds for the earpiece faceplates. This partial mold development approach lowers the barrier for brands to implement their own designs while reducing development costs. Beyond superior performance, the earphones feature meticulous ergonomic details that snugly fit the ear contours. The skin-friendly liquid silicone rubber hooks ensure near-zero discomfort during wear. Their battery life sufficiently supports all-day standby for business professionals, while the premium aesthetics reflect their distinctive taste.

The OWS open wireless earbuds, leveraging this open-style gas transmission method, represent both a current market trend and a consumer preference trend. The open design enhances wearing comfort-type while preventing the hassle of earbuds falling off and getting lost. Correspondingly, it reduces the probability of certain dangerous accidents caused by inability to clearly hear external sounds in noisy environments.

TWS/OWS-type earphone production in East China has largely shifted to inland regions. Most facilities remaining in Shenzhen and Dongguan are product material warehouses, along with finished product inspection and packaging standard production lines prior to shipment. We welcome everybody to place OEM/ODM orders.