Both Aluminum and plastic can be good materials for speaker cases, but each has different advantages and disadvantages.

Today we will compare the main difference from 3-dimensional from —–a manufacture perspective.

1. Intuitive Advantages

1.1 Aluminum case: looks high-end, expensive.

1.2 Aluminum case: heavier feeling that, the same feeling you got from iPhone VS other brand early plastic cell phone.

1.3 The exterior color is more durable

1.4 ABS plastic case: ABS, A low-cost thermoplastic that’s resistant to chemicals and has some impact resistance.

1.5 ABS plastic case: Able to provides visual clarity.

1.6 ABS plastic case: Able to make more complex design.

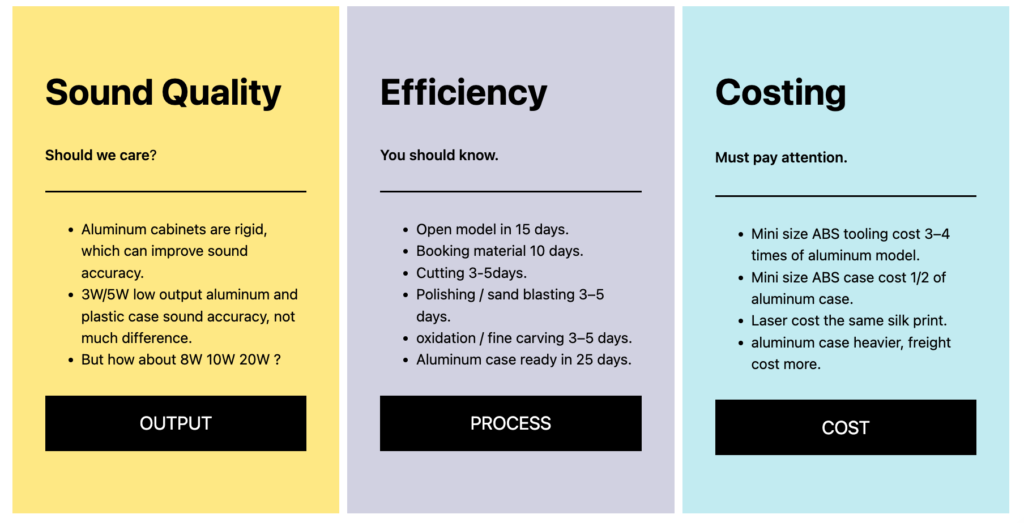

2. Sound Quality Advantages

The Same Structure and The same parameter configuration, Metal Case Sound Quality Better Than Plastic Case.

Why?

Metal cabinets are rigid, which can improve sound accuracy, and it is heavier can support stronger bass vibration ang louder volume. But Plastic enclosures can’t hold the same vibration or volume, so the plastic case have slightly worse sound quality.

3. Efficiency

For example, NEW model order 3000pcs. First order that aluminum case delivery time may be faster. But re-order aluminum case produce have more process which may be much slower.

Specially when you’re not order from the direct aluminum speaker factory. The market is tough, small quantity hard to do the oxidation/fine carving. Which may cause order delay and cost floating.

| Plastic case produce process | Time | Time | Aluminum case produce process |

| Open molding | 35 days | 15 days | Open molding |

| Booking material | 3–5 days | 10 days | Booking material |

| Injection | 3 days | 3–5 days | Cutting |

| Surface electroplate or oil spray | 3 days | 3–5 days | Polishing / sand blasting |

| Silk print/laser logo | 3 days | 3–5 days | Oxidation / fine carving |

| 3 days | Silk print/laser logo | ||

| TOTAL | 47–52 days | 37–52 days | TOTAL |

| Re-order | 12–17 days | 22–37 days | Re-order |

4. Costing

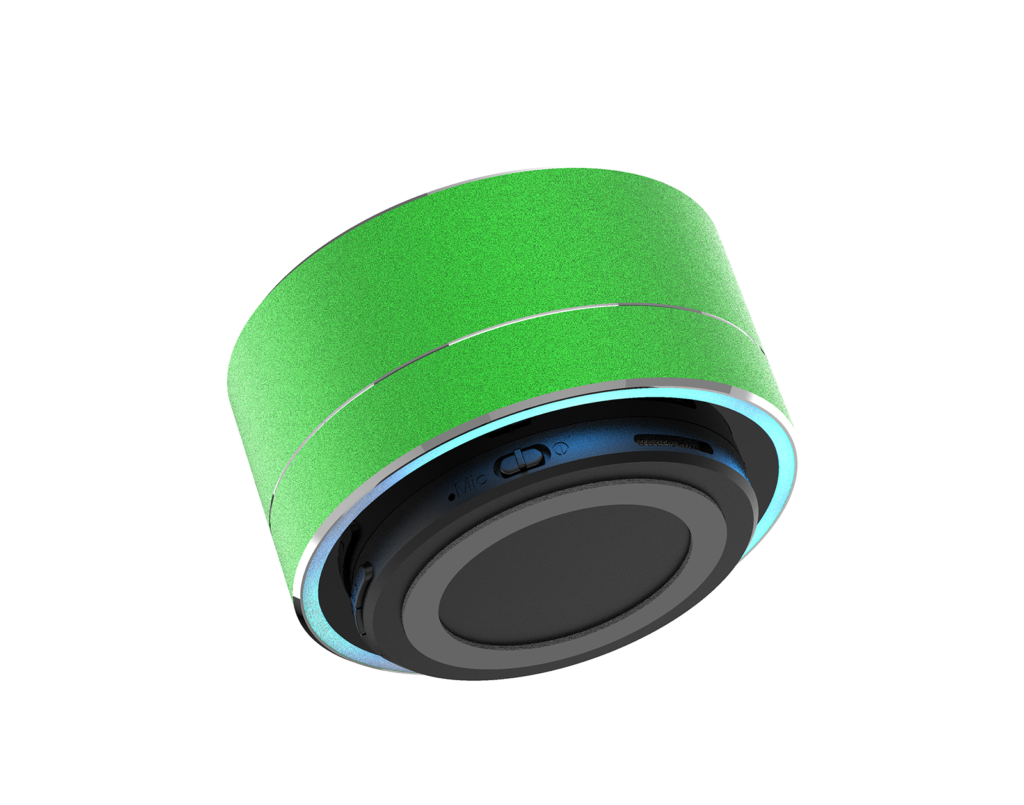

Let look at this classic promotion aluminum case Bluetooth speaker as a sample.

Attention: The order quantity is always the major key fact to reducing all cost.

Particularly in the current situation where the market is very sluggish, and the consumers’ consumption expectations are also getting lower and lower. Economic pressure forces material suppliers and manufacturers to all have to lower prices to maintain sales volume, or even to survive.

Meanwhile, in terms of product design, only the most essential functions are retained, and other additional functions are gradually cancelled. For example, for Bluetooth speakers, basically only the power on/off, previous/next track/hands free for call functions are retained, and there are basically no other functions.

Based on all the above reasons, the cost of product has been very close to the raw materials. The quantity of orders directly determines the price of this product.

Finally, it still needs to be emphasized that different manufacturers have different resource allocations. So, even if the price of the product is already very close to that of raw materials, but when you superimpose necessary expenses such as labor and working hours, price differences begin to show.

It should be noted that this case is rather special. For this type of speaker here, the replaceable shell part, if it is a plastic shell, just happens that a ring shape requires a separate mold. Then, if it is of other shapes, maybe its shell can be produced with the other plastic main body parts of the speaker in the same mold, and there is no need to calculate a mold renewal fee separately. Therefore, this example is only a special case and not a very common one.

Please note that in the example here, the mold costs of other main parts of this product are omitted and not calculated.

| Plastic case | cost | cost | Aluminum case |

| Molding cost | $1500 | $750 | Molding cost |

Here is one more thing, very important.

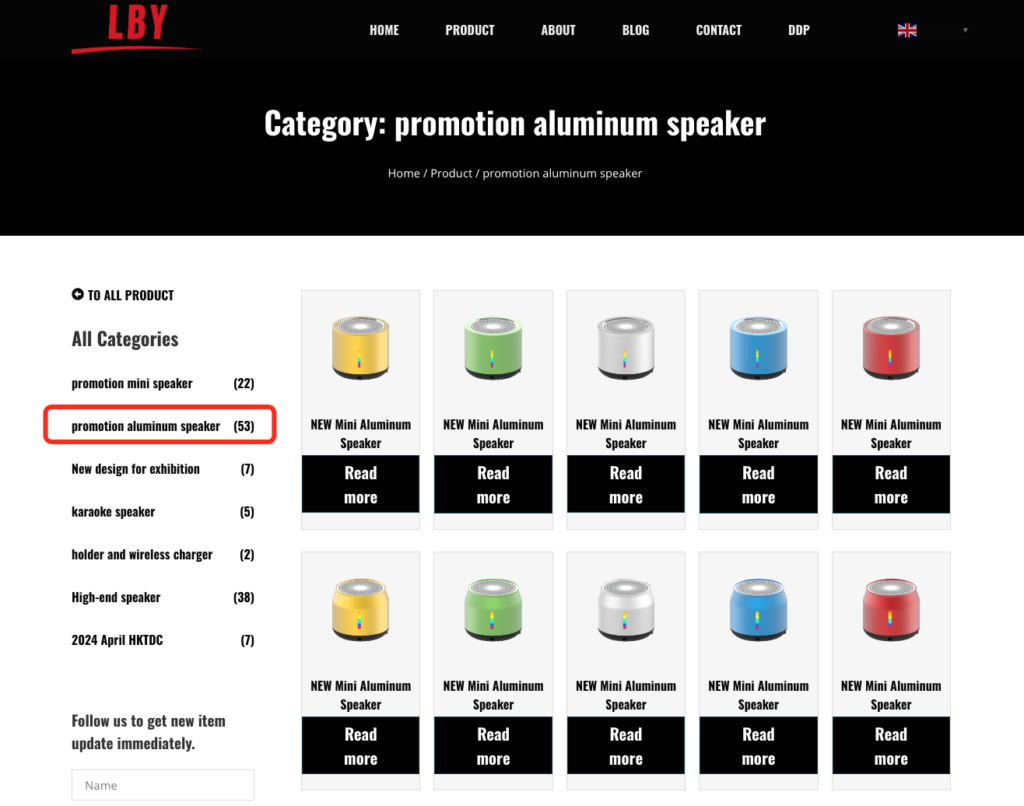

If you quickly reviewed our “promotion aluminum speaker” product category. You will find out there are about 15 aluminum portable speakers model. In 3 different size, With or W/O RGB lights.

Their shapers are mainly circular. Why?

- circular, easy to open molding, cost cheaper.

- easy to assembly, save labor cost and working hour.

- Size and thickness are the main factors determining the price of aluminum alloy shells.

- Each model we have tested over 20 kinds of speakers and PCBA parameters to make the sound quality of speakers sound loud, clear and stereoscopic enough.

- From the production perspective, the defect rate of the aluminum alloy shell is lower than that of the plastic shell.

- Our goal is to offer you sufficient choices of aluminum (metal) speakers for speakers under 5 dollars.

OK. You are a purchaser or wholesaler or brand owner. Then you need to pay attention now. Remember to mark it as the key point.

——Our goal is to offer you sufficient choices of aluminum (metal) speakers for speakers under 5 dollars.

——Based on these aluminum alloy products we made ourselves, we can obtain the following rules.

- The aluminum alloy shell is 0.2 to 0.5 US dollars more expensive than the plastic shell as a whole.

- For the speakers with the same model configuration, those with aluminum alloy shells will have better sound quality than those with plastic shells.

- The cheapest and smallest-sized aluminum alloy speaker actually weighs about the same as the product with a plastic shell, so the shipping cost is also similar.

- The aluminum alloy shell is relatively more durable in appearance than the plastic shell. The aging and discoloration problem of the plastic shell will be more obvious after one year. But for the aluminum alloy, a part of its color will fade, but on the whole, it does not affect its appearance.

What kind of purchasers do you think are more suitable for choosing aluminum alloy speakers?

Additionally, we believe that aluminum alloy speakers are actually very suitable for wholesaler customers. Because if the wholesaler can complete the packaging design and the printing of the LOGO or the laser engraving of the LOGO by themselves, then it will have more advantages in local customization. Because for aluminum alloy, if you laser engrave a name or a special pattern and then give it as a gift to other friends, it is very memorable. If it is just ordinary printing, then maybe after the test of time, the LOGO will change color or fall off soon. There will be such problems. This is an indelible advantage of aluminum alloy.

Moreover, the aluminum alloy shell is more stable. If the sales cycle of these wholesaler customers is relatively long, then the storage conditions for the plastic shells will be more strict. Otherwise, for the surface treatment of the plastic shell, such as oil spraying, the detachment of these oils or becoming very greasy will all be problems that greatly affect the sales of this product.

As for the market rule itself, when people choose to reduce consumption or restrain their own consumption during the market downturn, when they have to consume and select products, they should be more cautious and want to choose some more durable and valuable products. Then, actually, for speakers with similar prices, aluminum alloy speakers are actually a choice that consumers tend to prefer. However, the response of aluminum alloy speakers in this market is not particularly strong. Most purchasers still decide based on the price factor and still purchase more audio products with plastic shells. Well, but we have received feedback on their actual sales situation, that is, the market is very sluggish, the sales are not good, and the sales volume is continuously decreasing. I’m not sure if giving consumers a more reasonable choice can promote sales volume, but I believe this can be regarded as a method worth trying.

Have you often heard suppliers complain that innovation is very difficult in recent years?

Production and manufacturing is not working behind closed doors. Therefore, we also hope to receive opinions from a wider range of users to optimize our products and production lines.

In view of the fact that many Chinese manufacturers rely on the form of design IDs provided by customers to complete production and manufacturing, the ability of some independent innovation and research and development is still relatively lacking. After all, production and manufacturing and marketing are actually two very independent modules. There are language issues. Including the sales market and the production and manufacturing end, which are actually in two different countries, and a lot of information is not so smooth. So, recently, many speaker factories and headset factories have reflected that if it is only from the aspect of appearance design to innovate, there are really no good IDs for appearance innovation, especially when the market price is still so low. So it has become very difficult for everyone’s design. So is it worth considering taking an alternative approach to meeting consumers’ purchasing needs and developing some new products?